How Do Venturis Work?

Venturi Flow Tubes are primary flow elements that employ the “Venturi Effect” to produce a differential pressure in a closed pipe. The flow element is capable of measuring any type of fluid, either liquid or gas, and has a long history of uses in many applications.

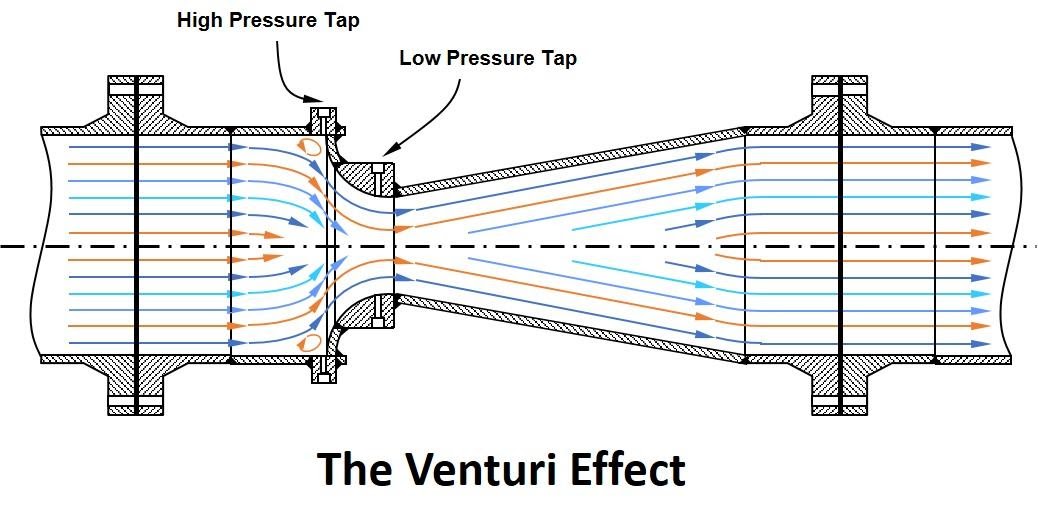

The Venturi Effect is the reduction in fluid pressure that results when the fluid is constricted through a throat section inside the pipe. As a result of this constriction, the fluid velocity increases as it passes through a smaller cross-sectional area, thus creating a decrease in pressure in accordance with Bernoulli’s principle.

The venturi flowmeter (shown above) requires two pressure taps, one located on the inlet side prior to the restriction, and the second is located in the throat section. Both taps are connected to a pressure gauge or transmitter to determine a ΔP pressure measurement. The resulting measurement is proportional to the square of the fluid velocity. Therefore, flowrate can be derived accurately and reliably. The venturi meter is designed to maximize the differential pressure while minimizing the permanent pressure loss to the system.

In addition to venturi flowmeters, Wyatt Engineering offers other differential producing products such as flow nozzles, orifice plates, and metering and restriction runs.