Wyatt Engineering Liberty Venturi Meters

Wyatt Engineering Liberty Venturi Meters

Fabricated Primary Elements

Features:

- High Accuracy

- Low-Pressure Loss

- Application-Specific Design

- Static Pressure Sensation

- Documented Performance

Description

Wyatt Engineering’s Liberty Venturi Meters are available as a fabricated series of modified venturi 01 flow elements that can be used to measure the flow of gases and liquids over an extreme range of temperatures and pressures in full pipes. The fabricated LVM maintains its accuracy over a greater range of flow rates, and incurs lower permanent pressure loss than either the ISO or ASME venturi designs.

Wyatt’s fabricated LVM series can be manufactured from virtually any metal or alloy. Each unit, therefore, can be designed specifically for your application.

Application

The fabricated series of LVMs are most often used in industrial applications where the flow stream demands specific material selection due to pressure and/or temperature, or the corrosive/erosive properties of the fluid being measured. LVM installations are found in:

- Power Plants

- Refineries

- Petrochemical Plants

- Cryogenic Processes

- Coal Gasification Plants

- Steam Custody Transfer

Flow Measurement Accuracy

For pipe Reynolds numbers greater than 75 000 and with a normalized piping configuration, the Wyatt-Badger LVM-U provides a flow measurement accuracy of ± 0.50% without flow calibration. With independent flow calibration, Wyatt Engineering’s venturi meters will provide the user with ± 0.25% accuracy.

Technical Specifications

Accuracy

For pipe Reynolds numbers greater than 75 000 and a normalized piping configuration, the Liberty Venturi Meter provides a flow measurement uncertainty of:

± 0.50% for standard meters and

± 0.25% for flow calibrated meters.

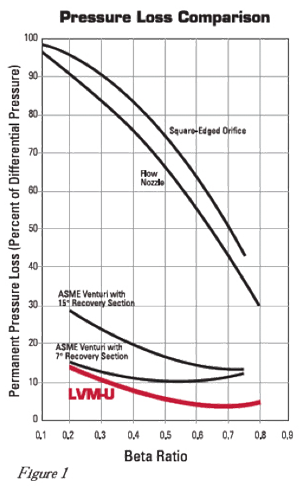

Pressure Loss

The permanent pressure loss of the fabricated LVM product line is significantly lower than that of short-form venturis, and, for most beta ratios, lower than that of long-form venturis as well. Call Wyatt Engineering for detailed headloss information on the design and process data for your application.

Beta Ratio

Wyatt Engineering can furnish fabricated LVM products with any beta ratio. This provides users with accurate flow measurement over a broad range of flow rates for a given line size.

Temperature Range

The fabricated LVM-U can operate over the fluid temperature range of -425 °F to +1200 °F (-250 °C to +650 °C).

Pressure Range/End Connections

Flanged end connections, per ANSI B16.5 for 150 PSIG through 2500 PSIG service, are available. Various end connections are also available, including plate, slip-on, weld neck, Van Stone, RTJ, or beveled (for butt-welding).

Piping Requirements

Designed for full pipe flow, LVM flow meters can be installed horizontally, vertically, or on an angle. For the recommended piping and installation requirements, refer to Wyatt Engineering Technical Manual for the LVM.

Signal to Noise Ratio

Within the specified flow range and piping conditions, the LVM will produce signal-to-noise ratios greater than 98%. This level of performance is essential for sensitive process control and reactive rate-of-flow control applications.

Design

The LVM hydraulic design produces a predictable and reliable discharge coefficient. The static pressure taps and smooth transition section minimize flow noise and lessen the effects of aging, corrosion, and/or erosion. Flow measurement of compressible fluids is performed accurately and reliably.

Available Options

Fabricated LVM units are available in different styles:

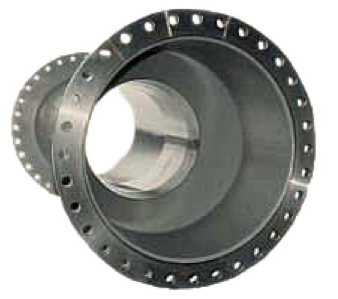

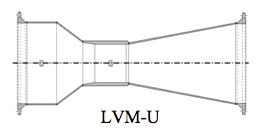

Model LVM-U s designed to the ASME Boiler and Pressure Vessel Code. It is typically used at operating pressures less than 400 PSIG (2 750 kPaG) and temperatures less than +500 °F (+260 °C). The unique construction of the LVM-U allows for custom designs. For example, the throat can be manufactured from a specific alloy for maximum abrasion resistance, while the exit cone can be constructed with a different alloy for corrosion resistance. For flexibility, multiple pressure connections are available.

Model LVM-U s designed to the ASME Boiler and Pressure Vessel Code. It is typically used at operating pressures less than 400 PSIG (2 750 kPaG) and temperatures less than +500 °F (+260 °C). The unique construction of the LVM-U allows for custom designs. For example, the throat can be manufactured from a specific alloy for maximum abrasion resistance, while the exit cone can be constructed with a different alloy for corrosion resistance. For flexibility, multiple pressure connections are available.

Model LVM-F is used for more demanding process temperatures and pressures. Its pipe-shell design can be constructed and certified to meet the requirements of B31.1 and B31.3. The LVM-F is available in flanged and plain-end designs. While the most common sizes are 6 inches (150 mm) and less, the Wyatt-Badger bar stock design has been made from 27” (685 mm) diameter bar stock material.

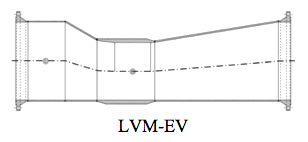

Model LVM-EV is designed for clients needing accurate and reliable measurement of multiphase flows. Whether for oil-water-gas-sand mixtures at the wellhead, slurry flows in mining, or in hydrotransport applications, Wyatt Engineering has a meter specific for these critical applications. With an uncertainty of ±0.50% and extremely low headloss (much lower than wedges or segmental orifice meters), the Wyatt LVM-EV offers proven energy savings and long term reliability. With optional sealed diaphragm pressure sensation, plugged taps are no longer of concern, and our SlurryShield® brazed interior surface greatly extends meter life over conventional, abrasion-resistant, and clad materials.

Model LVM-EV is designed for clients needing accurate and reliable measurement of multiphase flows. Whether for oil-water-gas-sand mixtures at the wellhead, slurry flows in mining, or in hydrotransport applications, Wyatt Engineering has a meter specific for these critical applications. With an uncertainty of ±0.50% and extremely low headloss (much lower than wedges or segmental orifice meters), the Wyatt LVM-EV offers proven energy savings and long term reliability. With optional sealed diaphragm pressure sensation, plugged taps are no longer of concern, and our SlurryShield® brazed interior surface greatly extends meter life over conventional, abrasion-resistant, and clad materials.

Model LVM-IF is designed for insertion within the interior of a pipeline and can be secured by companion flanges or welded directly into your pipeline. For more information on fabricated insert LVMs, see the Wyatt Engineering LVM-IF TechBrief.