Wyatt Liberty Venturi Meters

Wyatt Liberty Venturi Meters

Features

- High Accuracy

- Reliable Operation

- Energy Efficient (Low Headloss)

- Flexible Design for a Variety of Applications

Description

The Liberty Venturi Meter (LVM) is a primary flow element that accurately and repeatably measures the flows of liquids or gases in closed, full-pipe conditions. The LVM incorporates an efficient hydraulic shape with static pressure taps in the throat and inlet section. The LVM can be provided with either flanged or plain end connections. Wyatt offers full body pressure vessels and insert-type flow elements.

Applications

The LVM elements are often used in applications where the flow stream demands a specific material selection due to temperature and/or pressure, or the corrosive/erosive properties of the fluid being measured. LVM installations are found in power plants, refineries, chemical plants, cryogenic processes, water and sewage plants, custody transfer for steam and billing measurements.

Technical Specifications

Accuracy:

For pipe Reynolds numbers greater than 75,000 and a normalized piping configuration, the Wyatt Liberty Venturi Meter provides a flow measurement uncertainty of:

± 0.50% for standard meters without flow calibration, and

± 0.25% for flow calibrated meters.

Pressure Loss:

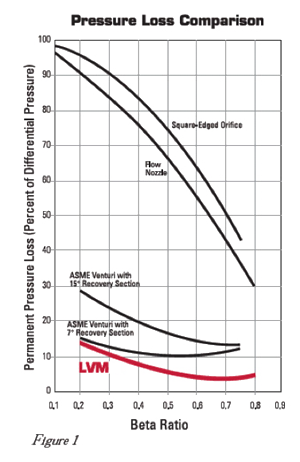

The permanent pressure loss of the Wyatt’s Liberty Venturi Meter is shown in Figure 1.

Beta Ratio:

Liberty Venturi Meters are available with a wide range of diameter ratios (d/D). This provides users with an accurate flow measurement over a broad range of flow rates for a given line size and set of process conditions.

Temperature Range:

Depending on the material of construction, the Liberty Venturi Meter can operate over a fluid temperature range of -425 °F to +1,200 °F (-250 °C and +650 °C).

Pressure Range/End Connections:

Flanged end connections per ANSI B16.1 for 125 PSIG and 250 PSIG service are available. A variety of other end connections is also available including: Mechanical joint flanges per AWWA C110 or C111, as well as plain-end designs.

Piping Requirements:

Designed for full-pipe flow, LVM flow meters may be mounted either horizontally or vertically. For recommended upstream piping, refer to the Wyatt Engineering LVM TECHspec.

Energy Considerations

Figure 1 above compares the headloss of the LVM design with that of other primary flow elements. The pressure recovery of the Liberty Venturi Meter means reduced pumping costs. Wyatt venturis have a shorter laying length and exhibit better recovery than typical classical and modified venturi meters.

The Wyatt Venturi is designed to provide a high degree of accuracy with unquestionable and predictable performance. Key to this design is the following:

Accuracy: Static inlet and throat pressure sensation provides a highly accurate, stable, and predictable flow measurement signal for flow rates with pipe Reynolds numbers as low as 75,000.

Reliability: Wyatt Venturi Tubes are free of protrusions and sharp-edged, debris-collecting annuli. Static pressure taps reduce flow noise. The internal contour is designed to minimize the buildup of solids and deter erosion, corrosion, and scaling.

Energy Savings: Wyatt Venturi Tubes operate with minimal headloss. This results in less energy consumption, lower operational costs, and a lower cost of ownership.

Available Options

The Liberty Venturi Meter is available in three styles for specific applications and installation requirements.

Model LVM-U is a fabricated full body venturi meter that is designed to meet ASMA Boiler and Pressure Vessel Code. The construction allows for a custom design to meet any set of process conditions. For flexibility, multiple pressure connections are available. To accommodate demanding applications with extreme temperature or pressure cycling, Wyatt can machine the element out of forged bar stock. Called the LVM-B, this design is most common for pipe sizes of 12 inches (300 mm) or less. Additionally, Wyatt can construct the LVM within a pipe shell. Called the LVM-F, this design is available with either flanged or plain end connections.

Model LVM-CI is a flanged cast iron venturi meter designed for either liquid or gas flow measurement. Typical throat materials are bronze and stainless steel. All valves, except for butterfly valves, may be direct coupled downstream for control purposes without any loss of accuracy. The LVM-CI can be supplied with flanges, mechanical joints, or plain ends.

Model LVM-IF is an insert-type venturi meter that is designed for insertion within the interior of the pipeline. The meter is secured in between two adjacent pipe flanges or welded directly in place. The insert-type venturi is best suited for liquids or gases that have low solids loading. The distinct advantage of the insert-type design is minimal weight, lower cost, and short laying length. The LVM-IF is constructed from all metallic components. An alternative style is the LVM-IL, which includes a metallic throat and mounting flange with a fiberglass or composite body. A third option is the LVM-IP, which is made entirely out of composite (or plastic) materials.