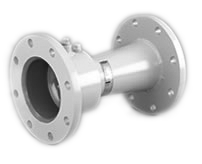

Wyatt Lo-Loss® Flow Tubes

Wyatt Lo-Loss® Flow Tubes

Fabricated Primary Elements

Features:

- Low Installed Cost

- Short Laying Length

- Low Pressure Loss

- Cost Effective

- Best Documented Flow Tube on the Market

Description

Wyatt fabricated PMT Lo-Loss® meters are differential producers that maintain their accuracy over a wide range of flow rates, and incur lower permanent pressure loss than any other differential producing flow device. These units can be made from virtually any material to address the different requirements of your applications. Lo-Loss® flow tubes are characterized by longevity of service and flexibility in design.

Application

The fabricated series of Lo-Loss® meters are often used in industrial applications where the flow stream demands intelligent decisions regarding materials of construction. This is due to extremes of pressure, temperature, or the aggressive nature of the fluid being metered. A short list of Lo-Loss® installations include:

- Power Plants

- Refineries

- Petrochemical Plants

- Chemical Processing

- Natural Gas Custody Transfer

Flow Measurement Accuracy

For pipe Reynolds numbers greater than 100 000 and a normalized piping configuration, the Wyatt PMT-U Lo-Loss® meter provides a flow measurement accuracy of ± 0.25% with independent flow calibration and ± 1.00% without flow calibration.

Lo-Loss® is a registered trademark of Wyatt Engineering.

Technical Specifications

Accuracy

For pipe Reynolds numbers greater than 100 000 and normalized piping configuration, the Lo-Loss® flow meters produce flow measurement uncertainties of:

± 1.00% for standard meters and

± 0.25% for flow calibrated meters

Pressure Loss

The permanent pressure loss of the Lo-Loss®, expressed as a percentage of the differential pressure, is the lowest of any differential producing primary element.

Beta Ratio

Wyatt Engineering can furnish the Lo-Loss® meter with a wide range of diameter ratios (d/D). By custom designing a Lo-Loss® meter for your application’s flow conditions, Wyatt can provide an accurate and reliable primary element with the low permanent pressure loss.

Temperature Range

The fabricated series of Lo-Loss® meters can operate over the fluid temperature range of -425 °F to +1200 °F (-250 °C to +650 °C).

Pressure Range/End Connections

The Lo-Loss® PMT-U is available with flanged-end connections, per ANSI B16.5 for 150 PSIG through 2500 PSIG service. Various end connections are also available, including plate, slip-on, weld neck, Van Stone, RTJ, or beveled ends (for butt-welding).

Piping Requirements

Designed for full-pipe flow, PMT Lo-Loss® flow meters can be mounted horizontally or vertically. For recommended upstream piping and installation requirements, refer to Wyatt Engineering Technical Manual for the Lo-Loss® meter.

Energy Considerations

Figure 1 compares the permanent pressure loss of the insert Lo-Loss® design with that of other primary flow elements. Figure 2 illustrates the substantial savings that are realized when using a Lo-Loss® Meter in a typical application. The pressure recovery of the Wyatt Lo-Loss® Meter means reduced pumping costs. High beta ratio Lo-Loss® Meters will recover up to 97.5% of the differential pressure produced. This is two to four times better than typical classical venturi devices as well as most modified venturi meters.

Using venturi tubes instead of orifice plates can yield significant savings, and using the Lo-Loss® Meter instead of venturi tubes can realize even further savings. For over 40 years, engineers have given their clients the benefits of efficiency and accuracy by doing just that.

Fabricated PMT units are available in four styles:

Fabricated PMT units are available in four styles: PMT-F is used for more demand-ing process temperatures and pressures. Its pipe-shell design can be constructed and certified to meet the requirements of B31.1 and B31.3. The PMT-F is avail-able in flanged and plain-end designs.

PMT-F is used for more demand-ing process temperatures and pressures. Its pipe-shell design can be constructed and certified to meet the requirements of B31.1 and B31.3. The PMT-F is avail-able in flanged and plain-end designs.